Precisely calculate CNC milling cycle times and optimize your quoting process.

Our expert engineering system contains extensive databases and proprietary formulas to accurately determine value added and non-value added times and costs. With our data on hundreds of machines, fixture types, cutting tools, and more, you can quote rapidly and confidently within +/-1% of your actual cycle times. Streamline your operations and increase profitability with Micro Estimating’s CNC Milling Cycle Time Calculator.

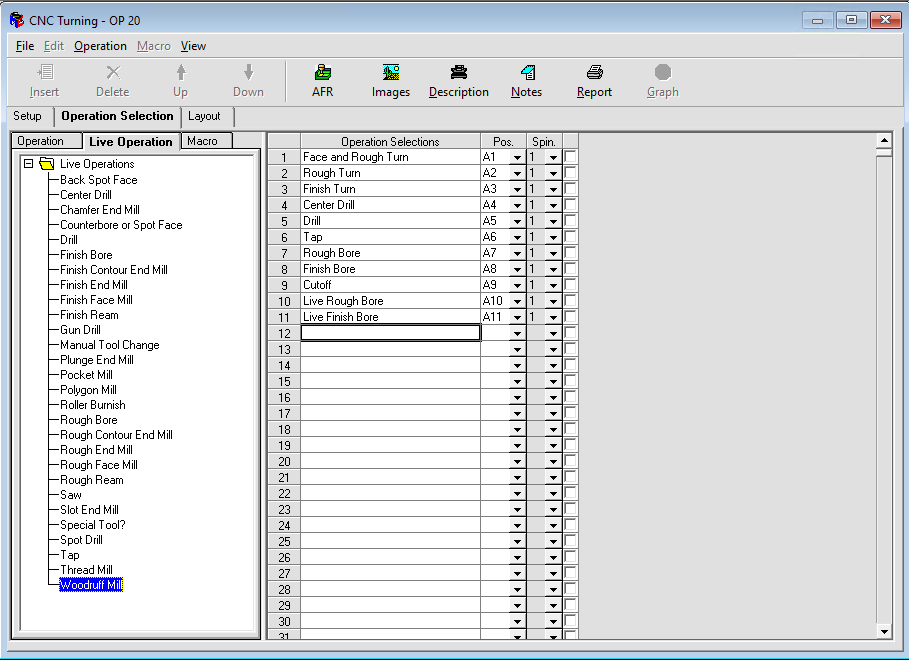

Precise and Efficient CNC Turning Cycle Time Calculation.

Save time and accurately calculate the cycle times for your CNC turning operations with Micro Estimating’s expert engineering system. Our extensive database and proprietary formulas ensure that you can quote rapidly and get within +/-1% of your actual cycle times. With data on hundreds of machines, fixture types, cutting tools, and more, you’ll have the precision you need to optimize your operations for maximum efficiency and profitability.

Optimize your CNC turning cycle times with precision.

Say goodbye to guesswork and optimize your CNC turning cycle times with precision. Our expert engineering system contains databases of materials, machines, factory operations, tooling, and more. With the ability to use your specific machine tools and access data on hundreds of machines, you can quote rapidly and consistently achieve cycle times within +/-1% of actual. Streamline your operations and improve efficiency today.

Accurate cycle times for precise quoting.

Don’t leave your quoting to chance. With Micro Estimating’s CNC Turning Cycle Time Calculator, you can achieve accuracy within +/-1% of your actual cycle times. Our machine tool emulation feature utilizes thousands of parameter combinations, ensuring that your quotes are precise and competitive. Quote rapidly and win more business with confidence.

Accurate and rapid quoting for precision machining.

Don’t waste time on manual calculations. Our CNC Turning Cycle Time Calculator uses activity-based estimating to accurately calculate material removal based on your parts’ features. With our extensive database and proprietary formulas, you can quote rapidly and confidently, getting within +/-1% of actual cycle times. Streamline your precision machining process and boost your accuracy with ease.