Accurately estimate CNC milling cycle times with Micro Estimating’s expert engineering system.

Our expert engineering system provides comprehensive databases and proprietary formulas to ensure precise calculations, saving you time and ensuring accurate quotes. Get within +/-1% of actual cycle times and quote rapidly with confidence.

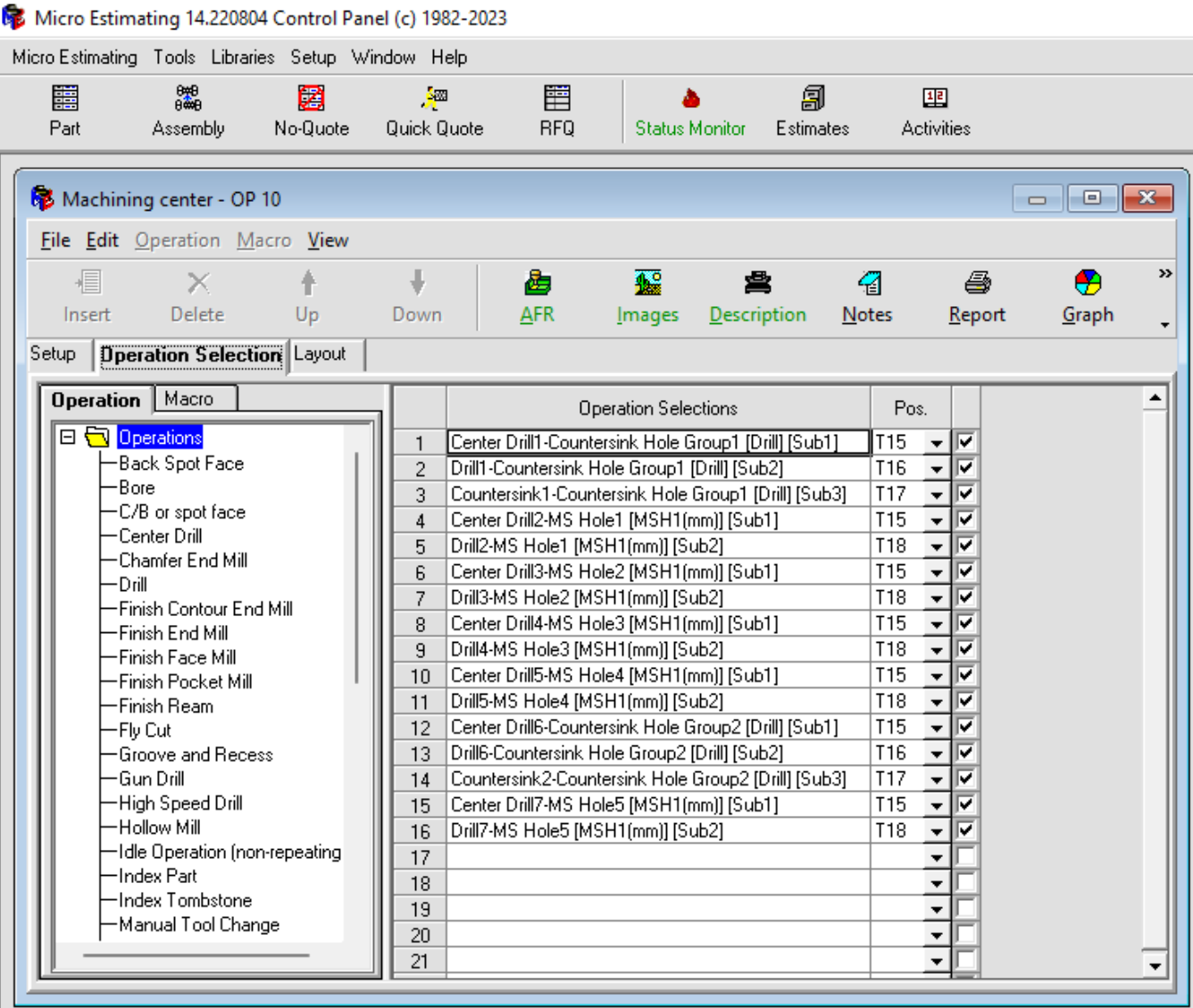

Milling Operations

Process Operations

Tool Position

Details Completed

Files

Optimize your CNC milling cycle times with precision and accuracy.

Our expert engineering system is equipped with comprehensive databases and proprietary formulas to help you accurately calculate cycle times for CNC milling. With data on hundreds of machines, fixture types, cutting tools, and more, our customers consistently achieve results within +/-1% of their actual cycle times, all while quoting rapidly. Say goodbye to guesswork and streamline your manufacturing processes with Micro Estimating’s CNC Milling Cycle Time Calculator.

Get accurate cycle times and quotes with precision.

Don’t waste time manually calculating cycle times and quotes. Our CNC Milling Cycle Time Calculator uses proprietary formulas and a vast database of materials, machines, operations, and more to provide accurate results within +/-1%. With options to add and edit machine tools, you can ensure precision in your estimates and streamline your quoting process. Say goodbye to guesswork and start quoting rapidly with confidence.

Optimize your CNC milling cycle time with precision.

Achieve unparalleled accuracy in your CNC milling cycle time calculations with our machine tool emulation feature. Our system utilizes thousands of parameter combinations to provide you with precise and reliable estimates, allowing you to quote rapidly and confidently. Say goodbye to guesswork and maximize efficiency in your operations.

Maximize efficiency with precise cycle time calculations.

Don’t waste valuable time and resources on inaccurate cycle time estimates. Our CNC Milling Cycle Time Calculator uses activity-based estimating to calculate material removal based on your parts’ unique features. With our precise calculations, you can maximize efficiency, quote rapidly, and get within +/-1% of your actual cycle times. Streamline your processes and boost productivity today.